Revetment & Groyne Rock Works.

A.Slope Profiling

B.Prior to any rockworks, base preparation is a must, this can be done via offshore or onshore process, once the reclamation already stablish and the rockwork area is clear from reclamation activity, With the

used of long reach excavator, The ground team will do the levelling / profiling of the seabed and slope of the reclamation fill, as per the design of the revetment base. With the used of the GPS attached to the exactor monitoring the slope and level of cut as per the engineer design.

C. Geotextile Installation

After the profiling the area to the design slope. Installation of the GEOTEXTILE MEMBRANE comes next. With the used of the long reach excavator. Geotextile spread to the slope of the revetment base. Spreader bar attached to the long reach excavator unrolled the geotextile. The underwater crew (Scuba divers) will check and ensure the geotextile installed correctly/ properly under water prior to the Rockworks installation.

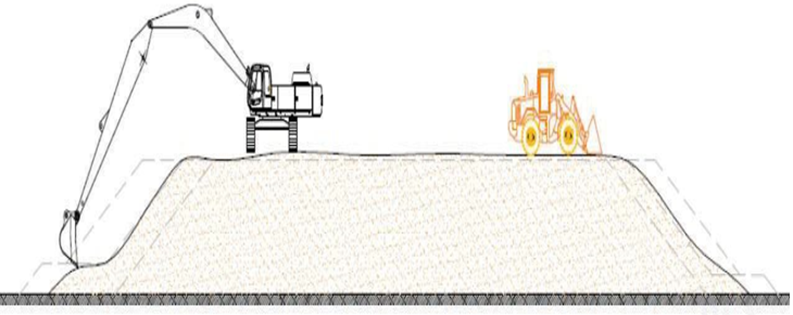

Once that there is enough reclamation shore / island, company will start to unload the Approved rock material trough a temporary access jetty. With the used of long reach excavator and along with the earth moving equipment then the team will start to install the quarry run, come along with the under layer rock ( if required) and to top it up with armour rock see diagram below/

REVETMENT & GROYNE ROCK WORKS PROCESS

1- Quarry rock laying/profiling:

Beigen to install of quarry run rocks using earth machines equipment, filling and profiling as per design slopes and levels.

2- Armour Rock laying/ profiling:

Above the quarry run layer start install the topmost of armour rock layer

3- Reclaimed part/levelling:

This process will start after all the rock works are completed or let say prior of the filling of the Geotextile shall carefully laid to cover with the adequate over lapping on the joint on the slopes profile required in order to prevent the sand fill enter rocks gap and proper water seepage to avoid scouring of beach sand filling.

4. Breakwater Rock Works.

Once that there is enough reclamation shore / island, AIMC will start to unload the Approved rock material trough a temporary access jetty. With the used of long reach excavator and along with the earth moving equipment AIMC team will start to install the quarry run, come along with the under layer rock ( if required) and to top it up with armour rock see diagram below.

Breakwater is a permanent structure constructed at coastline areas to keep protects against currents, waves, tilde streams, and also the storm surges part of a coastal line beach.

Breakwater are installed to minimize the erosion of the coastline like beaches, sandy exit channels, slope erosion … etc. and to protect anchorages, helping isolate vessels from marine hazards such as wind driven waves. The breakwater also protects marine boat jetties, slipway, loading/offloading areas,

5.Imported Beach Sand.

Beach sand filling & profiling.

Prior the filling and profiling of the beach sand. The reclamation fill shall properly level to the design level of the imported beach sand and the geotextile is properly laid and prior the filling process.

This levelling can take place either by offshore or on shore it. The final last step is the cleaning and housekeeping of the newly laid beach sand prior to hand over.

Company will make a stock file yard for the delivery of the Beach sand fill material on site. This stockyard will be the next stage will take place.

A. Imported beach sand screening

From the Temporary Stockpile of beach sand, company will set a sand screening machine to ensure the that the imported beach grain sand will be fill on the newly beach.

The back-hoe excavator will load the sand to the screening machine,

The Machine will separate the good sand to unwanted fill material.

The wheel Loader will load the good sand to the dump truck to the site area.

B. Beach Sand profiling

C. Geotextile Installation for Required Area

D. House Keeping Clearing Unwanted Material over the Newly Laid Imported Sand

5. Environmental Control.

Company is certified for ISO 14001, the International Certificate for Environment Management System standards. This system will be implemented on the project in terms of, legal requirements, environmental aspect / impact assessment, control measures, inspection/auditing and monitoring.

• Legal framework

Company will comply with federal environmental laws and relevant ministerial decrees, in addition to Abu Dhabi technical guidelines for excavation and disposal in the Emirate of Abu Dhabi, and the guidelines for standard limits for pollution to Marine Environment, which were set by Environment Agency of Abu Dhabi (EAD).

• Inspection/Auditing

In line with company’s EMS requirements, periodic inspections are conducted on site in order to specifically check effective implementation of the project environmental requirements and verify consistency of control measures with identified environmental impacts.

Quality control

The project team will follow the procedures and work instructions of our Quality Management system and follow reporting guidelines set out for the PROJECT. Records are maintained for various aspects of the work to provide traceability.

6. Related Codes & Standards

All work shall be performed in accordance with the international codes and standards, unless otherwise specified in project specification.

7. Site Health & Safety

Already established temporary rest areas are to be utilized for site labours.

A suitable first aid box will be made available and a qualified first aid representative will be supplied by Contractor. All equipment operatives will be registered and will have copies of their certificate with them for inspection

All personnel will be issued with the necessary PPE (Personal Protection Equipment) and will be expected to wear it at all times on site. Special PPE will be issued as necessary in the hazardous locations following site induction and or issue of a permit to work.

During site induction all personnel will be made aware of the site rules, Emergency Procedures. These will be adhered to at designed place.

Equipment operatives are familiar with the policies and procedures in place on projects of this size, with knowledge gained from the Client.

All heavy equipment should be checked by operator prior to starting daily work; especially the lifting equipment should be checked including its wire cable thoroughly.

All operations for the construction will be executed in accordance with the approved company HSE Plan.

8. Responsibilities

Responsibilities refer to the company HSE Plan and/or subject to the Client approval.

9. Emergency Response Plan

Emergency Contact List

At all project locations an emergency contact list will be displayed for project employees and visitor to handle emergency situations efficiently.

The Emergency contact list will be distributed to all at project locations such as offices, workshop, clinic, camps etc. and will be placed with great visibility strategic positions. The Project Manager must ensure that employees are familiar with the emergency contact list and that the document is updated when required.

The Project Manager must ensure that local authorities are aware of the project existence. Furthermore, he will arrange communication lines with emergency services and make preparatory arrangements for emergency situations.

10. Risk Assessment/ Job

Hazard Analysis

To assess the health & safety situation during the excavation works a Risk Assessment/Job Hazard Analysis will be made.

Prior to start any part of the work the following prerequisites will be completed.

• Client project induction training,

• PPE requirements met,

• Pre-task meetings,

• Operator certification verified,

• Permits and authorizations obtained, and

• Additional requirements when and where required.

All personnel involved in the works will receive training and will be certified as applicable for the works that they are carry out under this method statement.

11. Site Clearance & Demobilization of Personnel, Plant & Equipment

Once the site works are completed and accepted clearance of the site shall take place in conjunction with demobilization of personnel, plant and equipment. All the site office and machinery dismantled and removed from site.