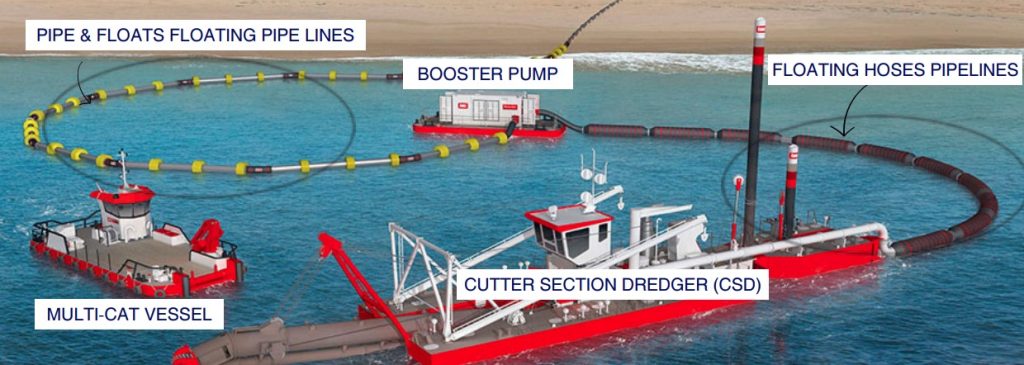

Dredging Fleet with booster station unit:

- CSD dredger connected with floating pipelines

- Booster station to be utilized for long discharge distance

- Workboat assistance and fix dredger floating pipelines works

Dredging utilizing cutter suction dredger, pipeline booster station and a pumping distance reaching up to 5 KM

Using a modular Trailer Suction Hopper Dredger (TSHD), with Hopper connection set up pumping of materials from seaside to create the proposed reclamation areas or artificial islands.

Trailing Suction Hopper Dredger: its self-propeller sailing dredger and not stationary dredger. The TSHD is required to sail during dredging operations. When the TSHD is approaching the reclamation proposals, basin area, borrow area, or as per client obtaining the NOC’s approval areas. this is the area where dredged material can be used.

the trailer will reduce speed and lower the trail pipe overboard. The suction head at the end of the trail pipe will be kept above the seabed until the scheduled dredging area has been reached.

Once very near to the proposed/scheduled area the inboard dredge pump will be started whereby the seawater that is taken in, prior to the suction head touching soil, will be pumped overboard or in some cases remain in the hopper. As soon as the materials starts sucked, the density meter, which is installed behind the inboard pump, an increase in density will be seen. Immediately the dredge operator will divert the mixture into the hopper closing the pump overboard valve, thus avoiding spillage of material overboard.

While dredging, the trailer will sail at a speed of 2 to 4 knots, depending on the dredge location, surrounding marine activities, sea condition and soil parameters. Due to the speed of the ship the drag head will loosen the bottom material. This way a mixture of soil and water can be sucked into the suction pipe, which will be loaded into the trailers own hold, the so called “hopper”. Water jets,

which may be constructed in the drag head, can assist in loosening the soil, hence optimizing the production.

The production of a TSHD depends on many factors, among which:

Soil characteristics such as.

– Situ density,

– particle distribution

– SPT/CPT values … etc.

– Dredging depth

– Weather condition

– Sailing routs & distance

– Marine traffic plan

– Tides status

The TSHD will go through a cycle of 4 sequency operations:

- Loading

- Sailing full

- Unloading

- Sailing empty

The dredging time required for filling up the hopper and the load per trip will vary depending on soil parameters, dredging depths and other circumstances.

The sailing time, both full and empty, depends on traffic speed limits, currents, tides, water depth, weather conditions, sailing distance and route to the unloading site etc.

For unloading time again soil characteristics are an important factor. The dredging operations continue 24 hours a day and 7 days a week.

Loading the TSHD

A TSHD has a certain load it can carry. This depends on soil characteristics such as situ density, particle distributions and other parameters. The quantity that can be loaded into the hopper is limited by volume and/or weight, given the TSHD’s specifications, or is a result of an optimization to determine the most economical loading time.

When the hopper is fully loaded, the suction mouth is raised, and the pumping system is shut off. The suction pipe will be hoisted and secured on board.

Sailing full

After loading, the trailer leaves the borrow area and proceeds to the area where the load will be unloaded.

The TSHD will sail through the designated channels which will be clearly marked by buoys from the borrow area to the reclamation area to minimize the risk of collision, hitting submerged pipelines and grounding. Per island a draft restriction for the TSHD will be given as a “standing instruction”.

Discharging

Once arriving at the designated working area, the speed of the trailer suction hopper dredger is reduced, the vessel is carefully positioned in the required location of the designated reclamation area then start offloading using one of these systems:

- Dumping

- Rainbowing

- Floating pipeline.

The TSHD landline systems shall be positioned or repositioned, whenever required depend on the project management requirements (Client). so, to pump or place the dredged material evenly poised, over the reclamation area.